Navigating Welding Inspection Gilbert Arizona: Important Insights for Market Professionals

Navigating Welding Inspection Gilbert Arizona: Important Insights for Market Professionals

Blog Article

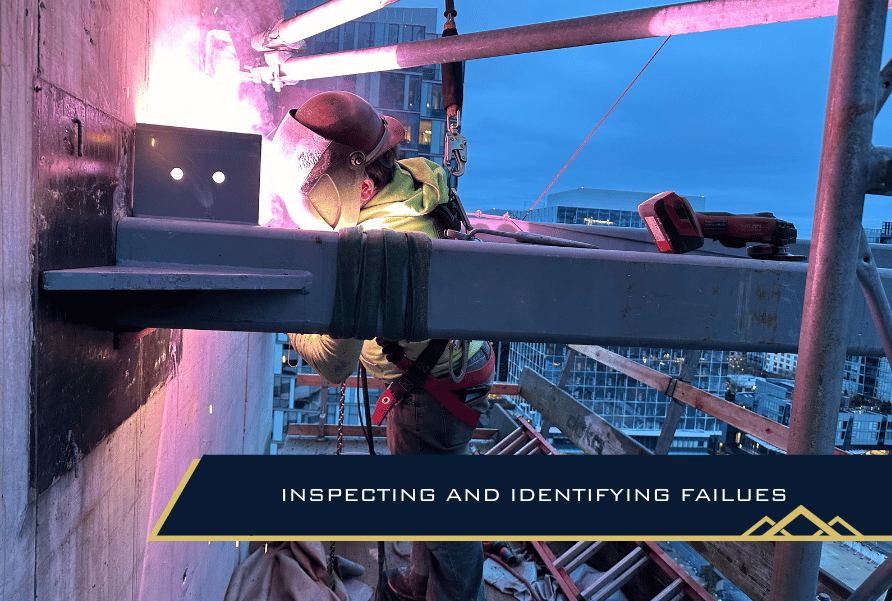

Welding Inspection Demystified: Secret Processes, Devices, and the Crucial Duty They Play in Preserving High-Quality Welds

Welding examination acts as an essential backbone in the guarantee of structural integrity and quality in welded joints, affecting various sectors from building and construction to manufacturing. This procedure is not just a procedure; it encompasses important techniques such as visual evaluations and advanced non-destructive screening techniques designed to reveal flaws that can jeopardize safety. With a range of specialized tools at their disposal, inspectors play a crucial role in preserving high requirements. The complexities of these approaches and their ramifications for high quality guarantee remain typically neglected. What are the essential processes and tools that make sure these criteria are maintained?

Importance of Welding Assessment

Making sure the stability of bonded joints is vital in various industries, making the relevance of welding evaluation undeniable. The high quality of welds directly affects the security, efficiency, and durability of components and frameworks. In sectors such as building, auto, aerospace, and production, any kind of failing in bonded joints can lead to tragic consequences, including structural failures, tools malfunction, and death.

Welding inspection works as a critical quality assurance measure, guaranteeing that welds satisfy defined criteria and governing requirements. It identifies problems such as splits, porosity, and insufficient fusion that may compromise the toughness of the weld. By detecting these concerns early, welding assessment can stop costly rework, hold-ups, and possible safety risks.

Furthermore, welding inspection promotes compliance with sector standards and certifications, enhancing the trustworthiness of companies and their items. It also supports continuous renovation by providing beneficial comments to welding workers, enabling them to refine their processes and methods.

Eventually, the relevance of welding assessment can not be overstated; it is important for preserving top quality welds, making certain safety, and safeguarding financial investments across various industries.

Trick Examination Processes

Reliable welding examination relies upon a series of essential processes developed to evaluate the high quality and stability of welds. These procedures incorporate both non-destructive and visual screening (NDT) approaches, guaranteeing that any flaws are recognized prior to they jeopardize architectural honesty.

The very first step in the assessment process is a complete aesthetic exam, which enables assessors to assess welds for surface defects such as splits, damages, and insufficient fusion. Following visual checks, different NDT strategies may be employed, including ultrasonic testing, magnetic bit screening, and radiographic screening. Each approach offers unique benefits; as an example, ultrasonic testing can spot inner flaws, while radiographic testing offers an irreversible record of the weld's internal structure.

Furthermore, it is crucial to validate conformity with appropriate codes and criteria, ensuring that the weld meets industry specs. This includes inspecting weld measurements and positioning, as inappropriate measurements can cause failures under lots.

Crucial Devices for Evaluation

Frequently utilizing the right tools is essential for attaining precise welding assessments. A detailed set of evaluation devices assists make certain that welds meet rigid top quality requirements and specifications.

Among the key devices is the aesthetic assessment scale, which permits inspectors to examine surface problems, such as cleanliness and surface area finish, directly. Additionally, calipers and micrometers are essential for measuring weld dimensions and guaranteeing they satisfy called for tolerances.

For more in-depth assessments, ultrasonic screening (UT) devices is vital. This method uses high-frequency acoustic waves to discover internal flaws and analyze material thickness. Magnetic bit testing (MT) and color penetrant testing (PT) are vital for identifying surface area and near-surface problems, giving prompt aesthetic signs of prospective problems.

Welders should likewise be equipped with solidity testers, which review the mechanical buildings of the weld metal and base materials, guaranteeing they fulfill specific requirements. Documenting findings with digital assessment devices improves traceability and high quality control. By using these important devices, examiners can keep top notch welds, ultimately adding to the safety and reliability of bonded structures.

Usual Flaws and Their Discovery

Welds, comparable to the foundation of structural integrity in construction and manufacturing, can show different defects that jeopardize their performance and safety and security. Usual defects consist of porosity, cracks, undercut, absence of blend, and slag inclusions (Welding Inspection Gilbert Arizona). Each of these problems can manifest as a result of inappropriate welding techniques, inadequate product option, or poor prep work

Discovery of these problems can be attained through numerous non-destructive testing techniques, including visual assessment, find more ultrasonic screening, and radiographic screening. Each technique plays a critical role in identifying these faults, ensuring that the honesty of the weld is preserved and decreasing the risk of failing in crucial applications.

Ideal Practices for Top Quality Guarantee

Ensuring the highest high quality of welds is critical for architectural honesty and safety, especially in markets where the consequences of failure can be serious. To attain this, a number of best practices for quality assurance have to be implemented throughout the welding procedure.

First, a robust welding procedure specification (WPS) ought to be developed, detailing the required parameters for each welding procedure. This makes certain uniformity and adherence to industry requirements. Second, extensive training and qualification of welders are vital; skilled personnel are better equipped to produce high-grade welds and identify potential problems.

Regular evaluations need to be incorporated right into the welding process, making use of both non-destructive and aesthetic screening (NDT) techniques to find flaws beforehand. Routine calibration of inspection tools is crucial to maintain precision. Furthermore, recording all welding tasks, including inspections and rehabilitative activities, creates a deducible record that can be invaluable for top quality control.

Verdict

To conclude, welding inspection works as an important system for making sure the stability and dependability of welded joints across sectors - this link Welding Inspection Gilbert Arizona. With the execution of key evaluation procedures and the usage of crucial tools, organizations can efficiently recognize and deal with possible defects. Adherence to finest methods in quality control not just enhances security but additionally ensures compliance with sector requirements, eventually adding to the durability and performance of components and structures

Welding inspection offers as an essential backbone in the guarantee of architectural honesty and top quality in welded joints, affecting various industries from construction to manufacturing.Guaranteeing the integrity of bonded joints is extremely important in different industries, making the value of welding assessment undeniable.Welding assessment offers as a vital high quality control action, making sure that welds fulfill specified standards and governing demands. By utilizing these vital tools, examiners can maintain high-quality welds, inevitably adding to the security and reliability of welded structures.

In conclusion, welding inspection serves as an important device for making sure the stability and dependability of welded joints click now across markets.

Report this page